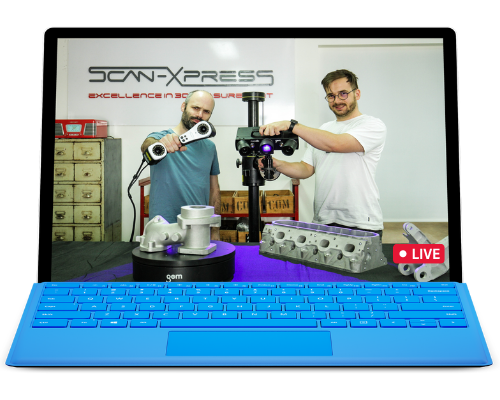

Scan-Xpress Applications

At Scan-Xpress, our goal is to help you grow regardless of your industrial application by providing the metrology, quality inspection & reverse engineering solutions that help you speed up quality checks, detect more defects, and design & go-to-market more efficiently.